OperaOpus MES - system for monitoring efficiency and implementation in the plant

System MES (Manufacturing Execution System) is a system of data collecting in the plant. By this system all effects are monitored and enforcement operations by work orders in the production, in a real-time.

The main characteristics:

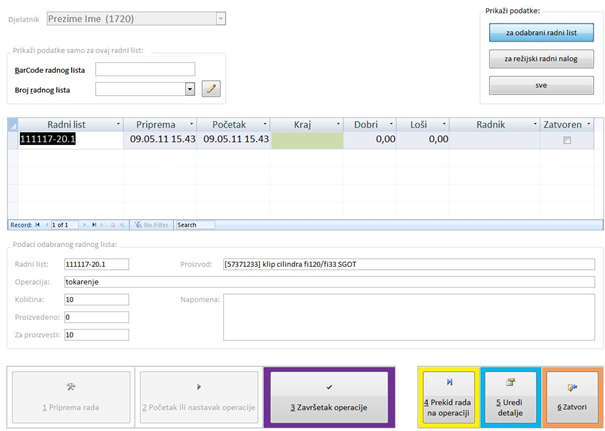

- Data input by a worker at the place of occurance (plant terminals)

- identification of workers by identification cards

- possibility of barcode operations and identification of operations using barcode readers

- controls of input (inability for one worker to open the same operation multiple times at the same time, open operation can only be quit or stopped, the inability of inputing data for closed operations)

- the possibility for recording work of several workers on same operation

- running the program in a way that it automatically launches a screen for the identification of workers to prevent entry into any other part of the program

- ability to record overhead hours (overhead work, delays, failures of the machine, waiting for materials, etc.)

- evidence of good products and scrap, and the actual times of starting and finishing work

- use of the touch screen

- reporting system with analysis on effect and assessment of hours necessery in production

- update of work order operations based on data collected, which is as well one of the elements for calculation of the real costs of production

- the ability to edit details and administration of the system with indications of false entries by the criteria of excessive expenditure of time (not reported completion of operation, etc.)