Opcenter APS

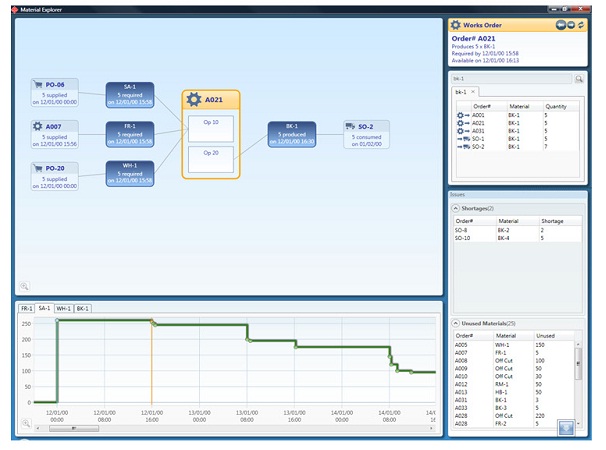

Opcenter APS (formerly known as Preactor) is the world's leading software for planning and scheduling of production, present in all industries. The system is installed in more than 3000 manufacturing enterprises in 67 countries. Opcenter APS offers a unique combination of ease of use, flexibility and integrability. The most often in practice integrates with ERP, MES and SCM solutions, and successfully implements in an environment with a discrete or mixed-model production until the production with process model.

From solutions based on the Opcenter APS system, uses have companies of all sizes: from the workshop with a few employees to large production systems with a number of related plants.

Research shows that the benefits that follow from the implementation of Opcenter APS system provide return of investment in just a few months. The users of Opcenter APS system can expect:

- 25% increase of productivity in manufacturing

- 50% reduction of work in progress and inventories

- 80% increase in timely delivery

In cooperation with the company Lean Scheduling Europe we have accomplished the integration of OperaOpus with Opcenter APS system.

By proper capacity planning and rapid reaction to all changes in the manufacturing process using this tool, it is possible to achieve:

- significant reduction in inventories of raw materials

- improving productivity

- on-line scheduling, simulation of "what-if" analysis

- shortening the production cycle by improving relationships with customers through increased speed of delivery and accurate information about the status of all work orders.

After implementing all the functionality described production company simply gets the right answers to the following questions:

- How much does it cost to manufacture a single product and what is its cost structure (fixed and variable, direct and indirect costs)?

- What is the earnings generated per unit of product when the buyer can be promised delivery of products and at what price?

- What material is necessary to purchase for the realization of the plan, how much will it cost and when it will be finished?

- What would happen if a certain order is declare as urgent, when it will be done, what other orders will be delayed because of this, and for how long?

- What will happen if a new machine is purchased, introduced overtime or second shift?

About Lean Scheduling International, LLC

Lean Scheduling International (LSI) is an international provider of Opcenter APS solutions with headquarters in Bradenton, Florida USA, with offices in Novo Mesto, Slovenia. LSI is the creator of numerous additional applications for Opcenter APS and specific solutions for specific industries.